Click here to download the story as a PDF

The New Kakinga Millers began operations in 2006 when Lucky Edson, a farmer who hoped to wring more value from his maize crop, rented and later purchased a milling machine.

Ten years later, the mill, which was up until then a sole proprietorship registered as a company Prior to working with U.S. Agency for International Development’s Farmer-to-Farmer, or F2F, program, their major concern was that there were production constraints and delays in transactions and thefts, causing them to operate at a loss.

Today, the mill’s goals include how to provide better accommodations for women and people with disabilities in their growing workforce.

Lucky, the mill’s managing director, said the mill asked F2F volunteers to look across the entire operation, from farm to mill, assess needs, and provide whatever training might be necessary.

“Now the first thing is quality,” Lucky said. “After the Farmer-to-Farmer training our farmers know the difference between poor quality maize and good quality maize. Then, as a company we have benefited because we used to lose one ton per 10 tons in rejects on quality ground, meaning that 1,000 kilograms would be lost. But now we are receiving good maize.”

Improved maize production began with an agronomist recruited by Catholic Relief Services, or CRS, the F2F implementer in Uganda. Farmers learned how to create and maintain healthy soil and quality harvest. They liked the results. So did the New Kakinga Mill.

Lawrence Rwabaingi is a maize farmer working with the New Kakinga Millers. He watched his crops improve while he added farming techniques like mulching to reduce erosion, and crop rotation to maintain healthy soil. He sees the broader impact of the training in the region.

“In fact, now the quality of every farmer is improving.”

While better quality grain was a top priority, mill operators had another set of challenges to surmount before they could see the hoped for results of improved maize quality.

Asiimwe Kizito is an accountant and the project coordinator at Kakinga where he has worked for 11 years. He cites accounting and record keeping as key challenges holding back the mill’s progress.

“Not all accounting functions worked,” he said.

They could not determine tonnages, what had been milled, what was already in stock. They could not accurately track sales in real time. They struggled to know who owed the mill money and to whom and when the mill needed to make payments.

“It was quite challenging at that time,” Asiimwe said.

CRS volunteers—one local and one remote— helped configure new software. The mill transferred its existing records into the new accounting system. Improvements came quickly.

“I remember we just dried maize grain in sunshine. We were cleaning by hand. Now we are using machines to clean.

We had only one small dumper, the tipper, that can carry maize from the farmers. Now we have several big trucks.”

—Asiimwe Kizito

“Right now, it is working very well,” Asiimwe said. “I can easily know each customer, how much he/ she supplied, how much we are owing them, the creditors, the debtors. I can easily get their statement every day. I can run the forecasts. The system guides me to do the financial statements. It also helps me to do the taxes.”

Another major improvement is stock management.

“I used to first go in the store and count each item,” Asiimwe said. “I would use source documents to calculate how much we dispersed and what we had in stock. It was quite hard to determine. Now you can easily do the forecasts for the next season based on your performance of the past year.”

Lucky Edson called their previous system a “pocket business.”

“I would come in the office and say to the cashier, give me 1 million,” he said. “He could give it to me. But now you cannot because the system doesn’t allow it. You have to seek written permission.”

Since the F2F training, Lucky said transactions are handled more reliably. And the business runs more smoothly as they are able to forecast and prepare for needs well in advance.

In the past, running short of supplies could catch them by surprise. Now the system alerts them when they need to purchase materials, service vehicles, or assess their stock.

“This is how business has stabilized,” Lucky said. “Even if I’m not around, I can know that today they’ve bought this many tons, they’ve processed this much maize flour. They’ve used this many containers, this truck has been refueled with this money. So, to me, as a director, my work has been simplified.”

And the mill has grown in quality and in number.

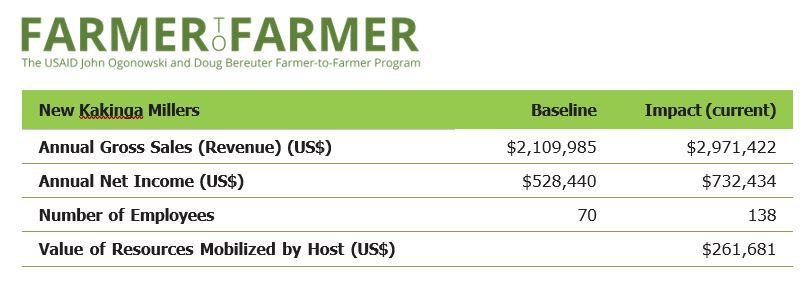

“I remember we just dried maize grain in sunshine,” Asiimwe said. “We were cleaning by hand. Now we are using machines to clean. We had only one small dumper, the tipper, that can carry maize from the farmers. Now we have several big trucks. When I started here we were around eight workers, and now we have 138 employees.”

They have happier farmers, too.

Mugisha Joseph, is a farmer, manages a co-op and serves as a village agent. He said working with the Kakinga Millers means producers know a market for their harvest is waiting for them when it’s time to sell. In the past, they often sold at a loss.

Kakinga Millers offers advance contracts, better pay, and reliability from season to season. In addition, Kakinga Millers offers market linkages to quality inputs like improved maize seed to their farmers.

Lucky Edson says that happy farmers are what the mill is building its future on.

“In the future we plan to make a group of companies, not to remain in my hands, but to remain a business for the community and the region or the country as well,” Lucky said

“Because we intend to open up a vocational school for the farmers’ children. Because we love farmers more than anything. If these farmers are not there, it means we have no business.”

“If these children are educated in a vocational school, it means that we shall never fail to get employees. Because we are moving to automated machines which will need technical people.”

He said the machines mean more efficiency and the hope of moving to an eight-hour workday. So, happier farmers, happier workers.

The CRS F2F program is a USAID-funded program focused on reducing hunger,

malnutrition, and poverty across six countries: Benin, Timor-Leste, Ethiopia, Nepal,

Rwanda, and Uganda. The program runs from 2019-2023 and aims to generate

sustainable and broad-based economic growth in the agricultural sector. U.S. volunteers

with agricultural expertise share skills and help build capacity for farmers through

short-term training and technical assistance projects resulting in more productive,

profitable, sustainable, and equitable agricultural systems.

Photos by Mountaga Drame for CRS